Pneumatic Valves & Control Applications

Pneumatics valves control the flow of air and other gasses. These valves are used in many applications but are most prominent in industrial applications. Typical pneumatic valves utilize a dual solenoid design. These solenoid actuators can work well in many applications. However, for some applications that are space, weight or power limited they can be challenging. Additionally solenoids can be noisy and do not offer proportional control due to their on/off nature.

Pneumatics valves control the flow of air and other gasses. These valves are used in many applications but are most prominent in industrial applications. Typical pneumatic valves utilize a dual solenoid design. These solenoid actuators can work well in many applications. However, for some applications that are space, weight or power limited they can be challenging. Additionally solenoids can be noisy and do not offer proportional control due to their on/off nature.

Piezoelectrics are a unique class of materials which when deformed by applied stress produce usable electric charge and when subjected to an applied electric field can deform themselves. In a pneumatic valve or control application piezo’s offer some very unique advantages over solenoids.

- Piezos have no audible noise

- Piezos have a fast response time, less than 10 ms

- Piezos are low power, and are capable of holding a position with virtually no additional power consumption

- Piezos are very thin

- Piezos can have an order of magnitude less mass when compared to solenoid solutions

- Piezos can be proportionally controlled, not just the binary on/off characteristics of solenoids

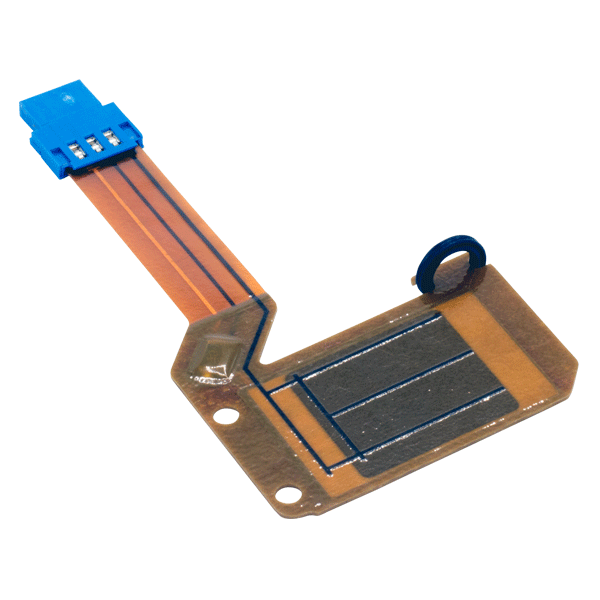

The most common piezoelectric materials are lead zirconate titanate (PZT). PZT’s are ceramics and have very good piezoelectric properties. However, if not designed or protected well PZT’s, due to their being ceramics, can be brittle and have failure issues, specifically when loaded in tension. At piezo.com we have two different technologies to drastically improve the robustness of bare PZT materials. One technology involves bonding the PZT material to a metal shim with a very durable and high strength bond. This technology provides a good amount of mechanical protection for the PZT. The second technology involves a full encapsulation of the PZT material using copper clad and etched materials. This encapsulation, or as we call it “packaging”, protects the PZT both mechanically as well as from the environment. Etching of the copper clad materials also allow for full customization of the electronic circuit needed to robustly connect the PZT to its drive, sensing or harvesting electronics.

Designing a piezoelectric pneumatic valve requires multi-disciplined expertise. Designed properly using piezo.com’s packaging technology, the piezoelectric valve can provide great value in harsh environment applications that need control of the flow of air and other gasses. With piezo.com’s over 40 years of experience designing complex piezo systems and subsystems we know we can partner with you to help your application be successful.

If you would like to meet with one of our Piezo Pneumatic Valve experts to discuss potential Development Partnerships, please fill out the form and we'll organize a meeting.